Articles | Technical

Fixing GIB® plasterboard horizontally to battens in non-performance walls

Wednesday, 28 August 2024

By Richard Fuller

To provide greater energy efficiency it is becoming more common to create a 45mm battened service cavity on the inside of the structural frame. How is it best to install the plasterboard over these battens?

1. Ensure timber framing is dry (less than 18% moisture content for intermittently heated buildings, recommended 8-12% where buildings are air conditioned or have central heating) and straight before fixing GIB® plasterboard. This will help prevent shrinkage, cracks, fastener popping or other problems in the future.

2. Fixing GIB® plasterboard sheets horizontally instead of vertically on walls reduces the number of joints, helping to achieve a more uniform appearance.

3. If a vapour/air barrier is to be part of the wall makeup this should not be directly behind the plasterboard. It is typically positioned between the structural frame and the battened service cavity.

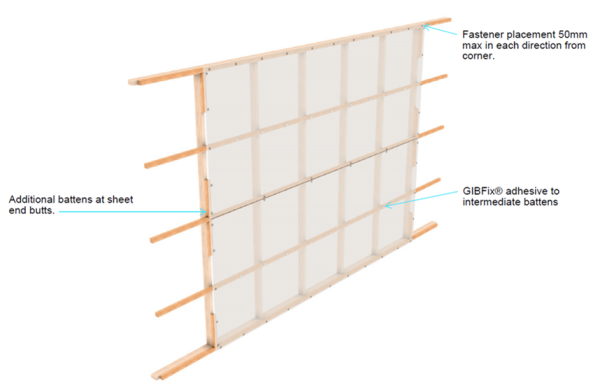

4. Timber battens with a minimum size of 45 x 45mm are to be installed at no greater than 600mm crs horizontally. Hold the plasterboard sheet tight against the framing approx. 5-10mm off the floor. Fasten the sheets @300mm centres to the top and bottom plates, with a single fastener per sheet @600mm centres along the horizontal joint, with additional battens at sheet end butts to allow for 300mm fastening centres. Intermediate battens can be adhesive fixed @300mm centres.

5. Use 6g GIB® Grabber® high thread screws with a minimum length of 25mm for 10mm GIB® plasterboard, and 32mm x 6g GIB® Grabber® high thread screws for 13mm GIB® plasterboard.

6. For 2.4m high stud walls, where you have a sheet butt end, a minimum 300mm long batten needs to be added.

7. Corner fastener placement to be 50mm in each direction. Fasteners must be placed no closer than 12mm from paper bound sheet edge and no closer than 18mm from sheet ends or cut edges.

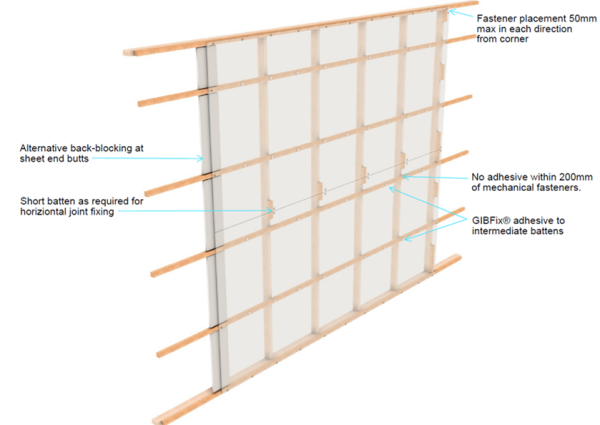

8. For wall heights greater than 2.4m a short batten may be required to provide the horizontal joint fixing, also the sheet setout is likely to mean the additional battens at the end butts are varied in length. To simplify this, it may be a better option to back-block this joint.

9. The advantages of back-blocking are reduced thermal bridging delivering greater thermal performance, and increased quality of finish. Because of these benefits it may be desirable to back-block the butt ends of 2.4m high walls.

10. Do not fix screws through, or closer than 200mm to the applied adhesive. This can cause the screws to ‘pop’ as the adhesive dries and shrinks.

11. Edges of openings (for doors and windows as an example) are prone to cracking. To reduce the risk of cracking it is strongly recommended that the sheet is cut around the openings and joints are formed no closer than 200mm to the edge of the opening.

Hold-down requirements for the bottom plates may need separate consideration depending on edge distance requirements.

Read next

Articles | Competitions

GIB® prize goes towards motorcross champions bid to regain New Zealand title

Wednesday, 28 August 2024 By Siobhan Page