Articles | Technical

How slab edge insulation effects GIB EzyBrace® systems

Tuesday, 18 June 2024

By Richard Fuller

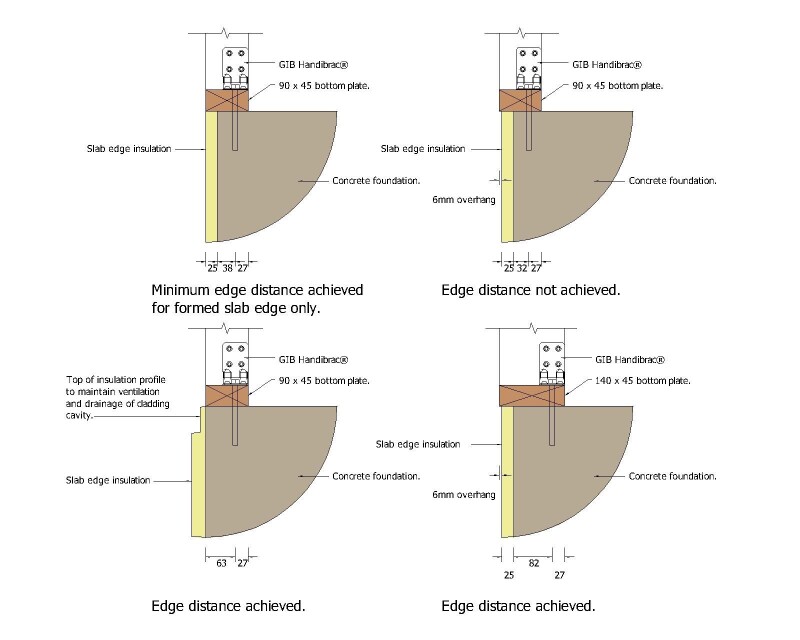

Due to recent NZBC H1 changes, slab edge insulation is becoming common in order to achieve higher slab floor construction R-values. This can make achieving the required edge distance for bottom plate hold-downs problematic.

Some GIB EzyBrace® elements require additional hold-downs. This is commonly achieved by using the GIB Handibrac® which is fixed through the timber bottom plate with a Bowmac blue hexagonal head screw bolt.

To ensure performance, the GIB Handibrac® requires a minimum edge distance of 35mm for formed slab edges, this increases to 55mm when fixing to a standard concrete floor with masonry header block. When using 90mm thick framed external walls, a typical approach would be to have the bottom plate overhanging the slab to allow for the slab edge insulation plus any required cladding capillary gap. All this means the required edge distance for the bolt may not be achieved.

If slab edge insulation is specified, careful consideration needs to be taken at early design stage. Such a small difference in measurement can have a large-scale flow-on effect! The type of foundations, cladding, insulation, and framing depth are all factors that affect the achievable edge distance.

If you have any questions call the GIB® Helpline 0800 100 442

Read next

Articles

The Wilson residence: Transforming problems into crowd-pleasers

Tuesday, 18 June 2024 By Vanessa Trethewey